When Steve Jobs and Steve Wozniak founded Apple, they would buy pieces of hardware, manufacture devices, and sell them. And Apple expanded in several areas until it was manufacturing printers, scanners, and cameras. When Steve returned to Apple in the mid-nineties, a comprehensive restructuring of Apple and a change in leadership began. Tim Cook was appointed as the responsible for operations and Jobs assigned him to solve the problem of factories, stores and production lines. Here, Tim Cook decided to close factories. Now, 20 years after his arrival at Apple, it appears that Tim has decided to revise his policy and reopen Apple's factories. Why did he close it old and open it now? Will Apple succeed in its policy that makes its future more like the past?

Why did Tim shut down Apple factories?

The decision was very shocking at the time, and Cook commented on this, saying, "It is as if you run a dairy factory in Apple, if the products are not always fresh then there is a problem." This is true when you have a factory, you will face a series of problems such as:

1

Preference challenge: When Samsung has a screen manufacturer, for example, it will not go to another company to buy a screen, but rather will commit to using its product often (sometimes there are deals such as Samsung Qualcomm deal with processors). With this, Apple will always find itself obligated to use the product it has created; If there is better in the market, its device will be lagging behind.

2

The challenge of abundance and impotence: When you have a factory you will have two red lines in production; The first is top which is the maximum and the manufacturer cannot offer any more; If they offer a great product and they ask you for more, but the factories are running at maximum power; The result is that you lose these sales because you cannot fulfill them. And vice versa, factories and production lines have a minimum. And there are workers who get paid permanently. What if you expect a certain sales volume and you produce and then the target demand does not occur and you start an abundance of inventory? You will have to stop production. But the workers are present and receive a constant salary even if the factory is not working. Rather, in production itself, there is a minimum level for manufacturing, otherwise the cost increases in an exaggerated manner. When it is not your factory you are not responsible for its employees; You just buy what suits you, leave the factory itself, and don't renew the contract if you want.

3

The challenge of expansionBuilding factories is a matter that takes months and sometimes years and requires huge sums of money; We remember that when Samsung was manufacturing Apple processors, it thought to expand its plant, and the cost was $ 4-5 billion. The same thing is LG, which is spending a similar amount now to build factories for OLED screens for the iPhone, and this takes nearly two years. Here, any expansion of the company wants it to spend billions and then wait a year or two for new production to arrive. Imagine that after this huge spending and time, you found that the popularity of the product decreased? Huge losses.

4

An army of laborThe more factories there are, the more workers will be. Samsung Electronics has 310 employees, and the overall Samsung Group has half a million employees. Foxconn has more than 800 employees, who were more than a million previously, while WalMart stores have 2.3 million employees, including 1.5 million in America only. As the number of workers increases, the problems increase and the administration needs a huge effort, especially that the basic category is "workers" and not engineers, and consequently low salaries and difficult and long operating conditions, strikes like we saw in Foxconn factories in China and even happened with Samsung workers in its TV factory in Egypt a year ago. 2014. Conclusion “Workers have more problems, bigger problems”.

There are many reasons and obstacles behind Tim Cook's decision to abandon and close factories, but we are satisfied with the above to give a general idea.

How did Apple produce its devices?

Tim Cook decides that Apple should cancel factories "manufacture products" and start buying; Thus, it has the advantage of choosing the best in the market; If the screens this year from Samsung were the best, it was with them, and if LG left Samsung and so on. As for the price obstacle, the cost of manufacturing the thing will be less than the cost of buying it, of course, from others. Here, the solution is the volume of orders for Apple. Companies are racing to bid lower to grab Apple's mega deal. Even Foxconn, we mention that Steve Jobs pressured them to reduce the cost of assembly, which made the company double working hours without real increases in wages, as well as using unsanitary conditions, which caused deaths and diseases among workers and famous suicides. The bottom line is Apple buys a huge amount and everyone seeks it.

Development, development and development

In the beginning, Apple only bought the best in the market. We mention the first iPhone, which was actually a Samsung device, the screen is Samsung, memory, storage, battery and processor from Samsung. But with the passage of time, Apple has unified that what is available in the market is less than its needs, so it has appointed an army of engineers whose job it is to develop patents and design products, whether technically, engineering or industrialized. With this, Apple won double, as companies develop, compete, and register patents to provide the best product, and then Apple comes and adjusts to the final form with the patents it owns. The result in front of us is that we saw the screen of the iPhone X and then the XS made by Samsung outperforming the screens of the Samsung phones themselves. That is, your product outperforms the one concerned. The secret is that the XS screen is manufactured with Apple and Samsung technologies, while the Note 9 screen is manufactured with Samsung technologies only.

So why are Apple factories?

Another straightforward example that can answer us is the iPad A12X processor that is manufactured at TSMC and this company does not only work with Apple, there are companies such as Qualcomm, MediaTech, AMD and others that manufacture processors for them. So what happened?

Any product that is needed is a combination of managing a production process and factories as well as developing the product itself “what is produced”. In the past, Apple used to do both, then completely stopped and said we buy the best; With time, it began to focus on developing some products, on top of which is the processor. And I found that it had already surpassed the processor in development, so why not continue? This secret is that we see an excess of news talking about:

◉ MLED screens: New screens that Apple has been developing for years, and Apple is seeking to provide its own alternative to the current OLED screens, but it takes time. Check out our article on these screens from this link.

◉ Communications segmentRecent news: Apple is working to develop its own SIM card.

◉ PMC chipPower Management Chips: Power Management Chips, sometimes called PMICs, whose function is to manage device consumption. For years, Apple relied on Dialog to manufacture it, but recently news emerged that Apple wanted to manufacture it itself, and then 3 months ago, Apple confirmed the news implicitly of expecting a contract worth $ 600 million in which the company would allow Apple to use its technology in manufacturing its products. That is, Apple bought the right to use Dialog technologies for three years.

◉ HealerFrank news: Apple said Apple plans to dispense with Intel in Mac computers and replace them with processors developed by it, but this is expected by 2022 at least.

The foregoing is nothing but a fraction of the news that talks about products that Apple is working on. We mean here that Apple develops the design and then relies on companies like TSMC to manufacture it. In the past, for example, Apple used to buy a Qualcomm or Intel SIM card, and these companies develop and manufacture in companies such as TSMC in the case of Qualcomm, and Intel owns its own factories “in a large percentage”. Apple wants to replace this development process to be a straightforward one. This manufacturing process is called Wafer fabrication.

Protection from crises and financial blackmail

Apple's philosophy was that when you buy the best product; There will be great competition in the market and you choose the best; But in past years Apple was shocked twice; In the field of OLED screens, I found an overwhelming advantage for Samsung, as it is the only one capable of providing the amount of screens that Apple wants. And Samsung imposed on Apple a huge sum for the screens, which prompted Apple to cooperate with LG to help it build factories to be an alternative to Samsung. The matter was repeated more often with Qualcomm, which swept the world of SIM cards and demanded Apple to pay double, meaning that Apple buys a SIM card and pays fees for using the chip. Here, Apple launched a legal war on Qualcomm, and it seems that it will lose it, and indeed it lost in China and recently Germany and Apple removed the 7 and 8 phones from stores there. .

Apple wants to protect itself from this. The market is no longer available with a competitor, and we choose the best, leave it and go to the competitor; The best is when it is one party that Apple will pay huge sums of money.

Conclusion

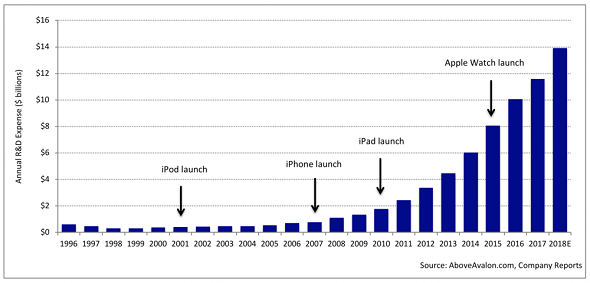

Apple closed factories to reduce problems and production lines, and as Tim said, to get rid of the dairy dilemma, to have fresh produce. Then, after years, I found the market either does not provide what it wants or does not provide it at a reasonable price, and here it returned again to manufacture, but this time it may be satisfied with the development and design and not the production stage itself. Do you see succeed? This step caused the R&D budget to drastically doubled, so the output would be in line with the spent, or the efforts would be wasted and the company lost money and so did the factories that abandoned them for its products.

20 comment